Are you troubled by these problems?

- Air bubbles in the transferred liquid causes a decrease in productivity

- The quality of the final product deteriorates when air bubbles remain in the raw material.

- I want to self-priming a high viscosity liquid with a non-contact pump.

- I want to operate a pump from a completely dry state.

Defoaming pumps can solve these problems!

Main Features of Defoaming Pump

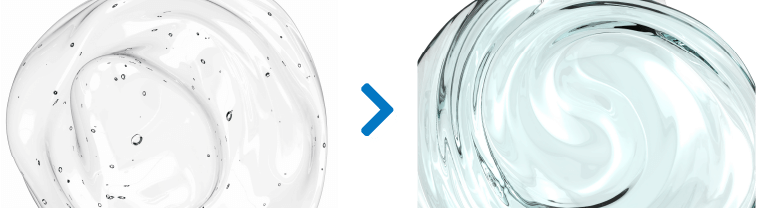

Eliminates air contamination problems!

A single newly developed model VQ lowers the risk of defects such as filling defects, molding defects, and quality deterioration due to air contamination.

*Photograph is just an image

No dedicated equipment, space, and time required for defoaming!

No dedicated equipment, space, and time required for defoaming

Conventional (5 processes)

When using a deforming pump (3 processes)

The introduction of a defoaming pump eliminates the need for a defoaming device, enabling cost reductions in equipment costs and improved productivity by slimming down the line and saving space.

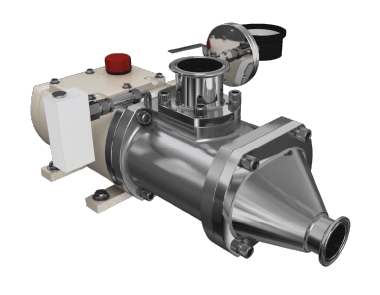

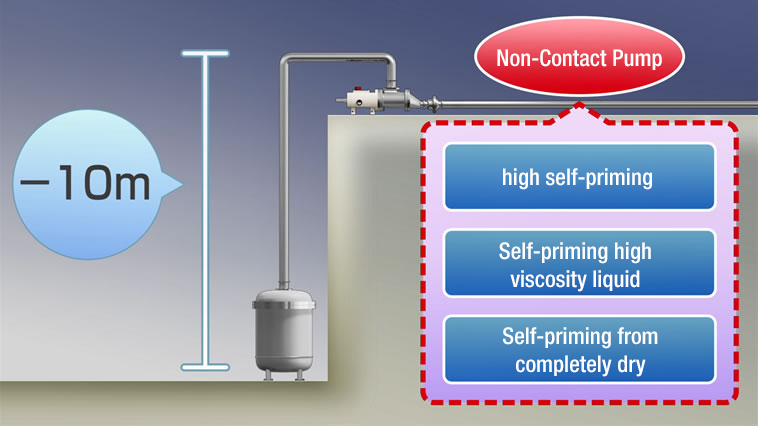

Sanitary construction and high self-priming power

I actually want to transfer liquid with a non-contact pump that has no contamination risk,

but the non-contact pump does not have enough self-priming power, so we have to transfer the liquid by hand….

The model VQ is the pump which improves such a situation.

The model VQ, which is a non-contact pump that can create a near perfect vacuum inside the pump, allows self-priming of high-viscosity liquids that could only be pulled out by conventional contact pumps.

Please also check this video to see actual self-priming.

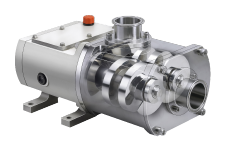

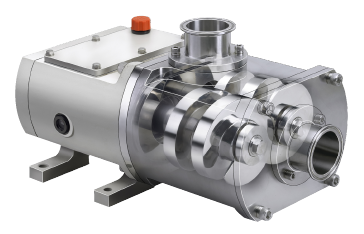

Inherits the performance of the twin screw pump model SQ!

The twin screw pump model VQ with defoaming function inherits the features of the twin screw pump model SQ, so it can be used safely in applications requiring non-contact, no shear, no pulsation, and no agitation.

- Non-contact

- No shear

- No pulsation

- No agitation

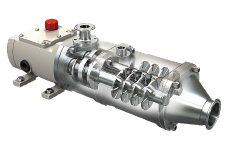

Image of defoaming transfer

While feeding the object to be transferred forward, air is removed from behind the pump’s inlet by utilizing a vacuum pump or ejector.

Please also check this video for more information on the de-aeration effect.

Case studies

Transfer liquid while defoaming

- Improving Product Safety.

Miso - To reduce the incidence of defects.

Gelatin - To stabilize the filling process.

Cosmetic creams - For self-priming and defoaming of high viscosity liquids.

Grease

Transfer of low-fluidity liquids

- To eliminate manual labor.

Tomato paste - Improving the working conditions.

Toothpaste - Streamlining production facilities.

Ground meat.

We also have a variety of other applications in addition to the above.

We also have test equipment available for rent (please inquire with your local representative for rental costs), so please feel free to contact us for more information.

Product Explanatory Video

Demonstration Videos

Example of defoaming

Example of self-priming of high-viscosity liquid

FAQ about our products

Q

- keyboard_arrow_right

- Want to remove contaminated air from liquid to be transferred

- Can you help with filling and molding defects caused by foam contamination?

A

Deforming pumps simultaneously remove air bubbles during transfer, which contributes to reducing filling and molding defects. Also, large equipment such as vacuum tanks and deaerators are no longer necessary, simplifying the line configuration. Since defoaming is not performed in batches, but continuously while transferring the liquid, it also contributes to improved production efficiency.

Attachments can be installed to match the type of liquid, and pumps can be installed in different ways to improve the defoaming effect.

Q

- keyboard_arrow_right

- I want a pump that requires no priming.

- When handling material with low fluidity, liquid hardly enters the pump without priming, which is troublesome.

Is there any way to get around this?

A

A defoaming pump, with which vacuum generator is equipped, can create a high suction force, allowing low-flow materials to be sucked into the pump without priming.

Q

- keyboard_arrow_right

- I need a pump with sanitary specifications and high self-priming power.

- I have a problem with the weak self-priming power of the non-contact sanitary pump I am using.

A

Defoaming pumps equipped with a vacuum generator can achieve self-priming of -10 m, which is the theoretical physical limit, even though it is a non-contact type. Since the pump is powered by the vacuum generator, self-priming performance remains unchanged even if the parts wear out.

Q

- keyboard_arrow_right

- I need a pump that can be used in conditions where it is prone to dry running.

- Due to the nature of the fluids we handle, dry operation often occurres and have trouble with parts breaking down.

A

Defoaming pumps are constructed so that the screws do not contact each other and the screw and casing do not contact each other, and no mechanical seal is used in the shaft seal section.

Therefore, there are no parts that can burn even in dry operation, so there is no problem even if operation is started in a completely dry state. This is a safe solution for lines that require dry operation or inadvertent mistakes by operators.

Q

- keyboard_arrow_right

- Want to handle items that are prone to leakage

- I want to feed a liquid that tends to leak from the pump, is there any problem?

A

Defoaming pumps are constructed so that no liquid comes in contact with the shaft seal (seal-less mechanism), eliminating concerns about liquid leakage.

Many of Fukko Kinzoku’s pumps are semi-custom-made and can be used even if other companies cannot.

We will recommend the best pump after discussion.

Please contact us for special liquids or liquids that you are having trouble with.

Main Specifications

| Connection method | Ferrule, IDF screw, JIS10K |

|---|---|

| Flow direction | Up to front, down to front |

| operating temperature limit | 100°C (standard specifications) *Special specifications available up to 200°C |

| bore | 1S to 3S, 25A to 80A |

| Drive method | Direct coupling connection |

Main part standard materials

| Housing | FC250,SCS13 |

|---|---|

| Casing | SCS16 |

| Screw | SUS316L |

| Shaft | SUS329J1 |