Thorough pursuit of cleanability!

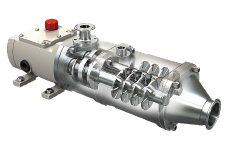

CIP cleaning by high-speed operation

High-speed operation allows the inside of the pump to be cleaned simply by flowing water. This allows a single pump to handle the entire process from pumping to cleaning, thereby reducing the cleaning time.

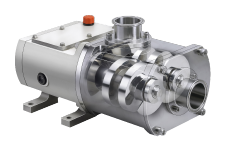

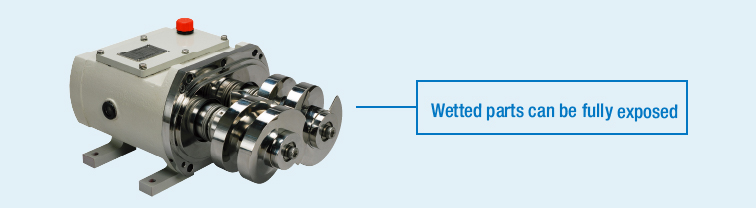

Easy to disassemble and clean

In addition to being structurally suited for CIP cleaning (cleaning in place), the wetted parts can be completely exposed by simply removing the casing, greatly reducing the time required for disassembly and cleaning.

Of course, the inner surface of the casing is processed to a finish in consideration of sanitation.

The mechanical seal at the shaft seal can also be easily cleaned because it can be pulled out along the shaft by loosening the set screw.

The outer surface of the casing can be buffed as an option.

further evolution by slide bar specification

Realization of “Easy Washing” !

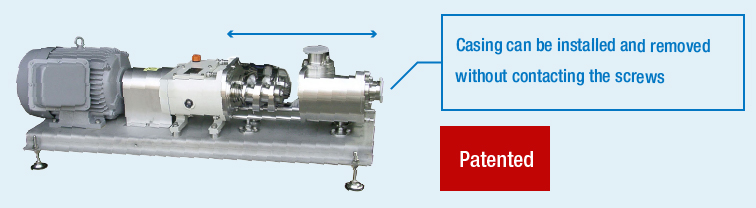

Slide bar (PAT)

The patented Slide Bar simplifies casing attachment and removal.

Two slide bars attached to the bottom of the casing allow the casing to be attached and removed without contact with the screw.

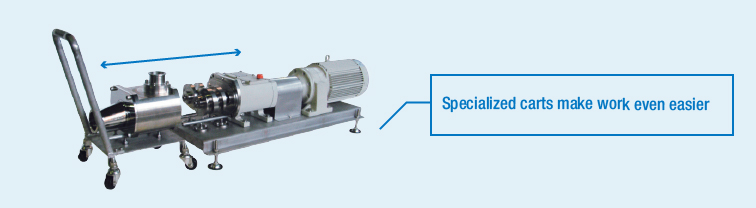

Moving cart with slide bar specification

By taking advantage of the twin screw pumps, which can be easily and completely cleaned, a single pump can transfer different types of liquids and be used at multiple locations.

Slide bar docking system

A casing transfer dedicated cart can be installed to make work even “easier”.

Slide bar and slide bar docking system specifications are also available for twin screw pumps with screw conveyors.

For more informationkeyboard_arrow_right