Are you having trouble with this?

- Want to improve productivity by reducing agitation time

- Want to save space at the production site

- Want to save time to clean the agitator after use

- Want to agitate and mix while suppressing the foaming

Blending pumps can solve that problem!

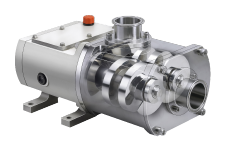

Main features of the blending pump model BQ

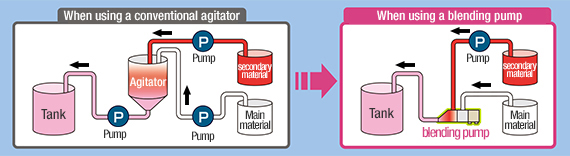

Significantly reduced production lead time

Up to now

When blending pump is used

The agitator becomes less needed with the introduction of the model BQ.

This saves space at the production site and reduces equipment costs.

In addition, production can be performed without the use of an agitator or agitator blades,

The time required to clean the equipment after the process is complete can also be significantly reduced.

Especially in small-lot production lines with frequent product changeovers and washings, this system can greatly improve the production process.

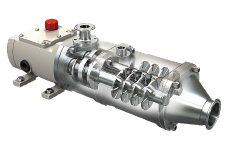

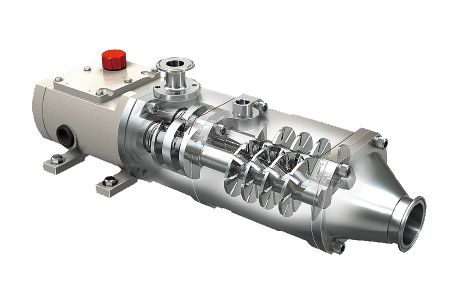

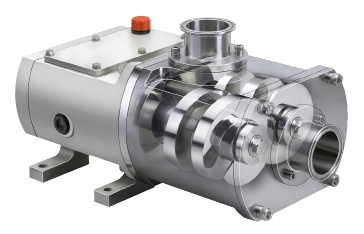

Succeeded the features of twin screw pump model SQ !

The twin screw pump BQ type with agitation function inherits the features of the twin screw pump model SQ, This pump can be used safely in applications that require non-contact and pulsation-free operation.

- non-contact

- pulsation-free

Examples of Application

Mixing different types of liquids into high viscosity liquids

Mixing liquids and powders

Kneading of high-viscosity liquids

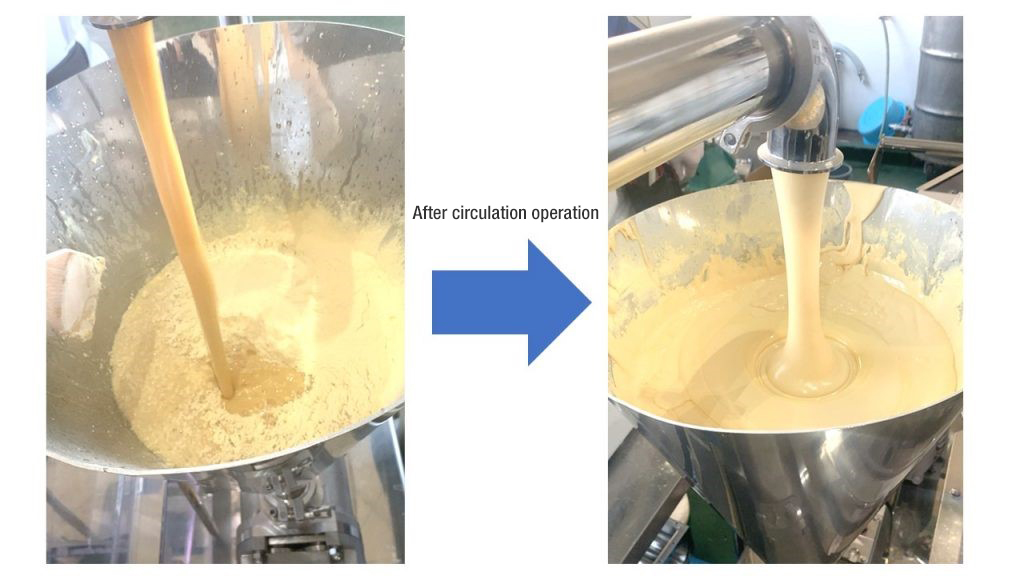

Example of mixing liquid and powder

Materials

Liquid: water (40℃) 6L

Powder: pancake mix 15 kg

Operating conditions

・Pump → piping → circulation in hopper

・Operation at 180 rpm for 10 minutes

・Powder is fed into the hopper little by little while circulating water

While powder can be seen floating on the water surface just after the start of powder feeding (left photo),

After 10 minutes of circulation operation, a thick, highly viscous, uniform liquid is produced. (Photo right)

This is the result of the effectiveness test for the introduction of the system,

The customer who approached us said

I have never seen such a uniform mixture,

They are very satisfied with the effectiveness of this product.

The results of this test have allowed us to,

By replacing conventional kneaders with blending pumps, it is now possible to expect improved quality and a significant reduction in the time required to disassemble and clean the agitator.

In addition to the above, the blending pump can be used for applications in all process industries, including the food industry, chemical industry, and cosmetics industry.

We also have test equipment available for rent (please contact our representatives for rental costs), so please feel free to contact us.

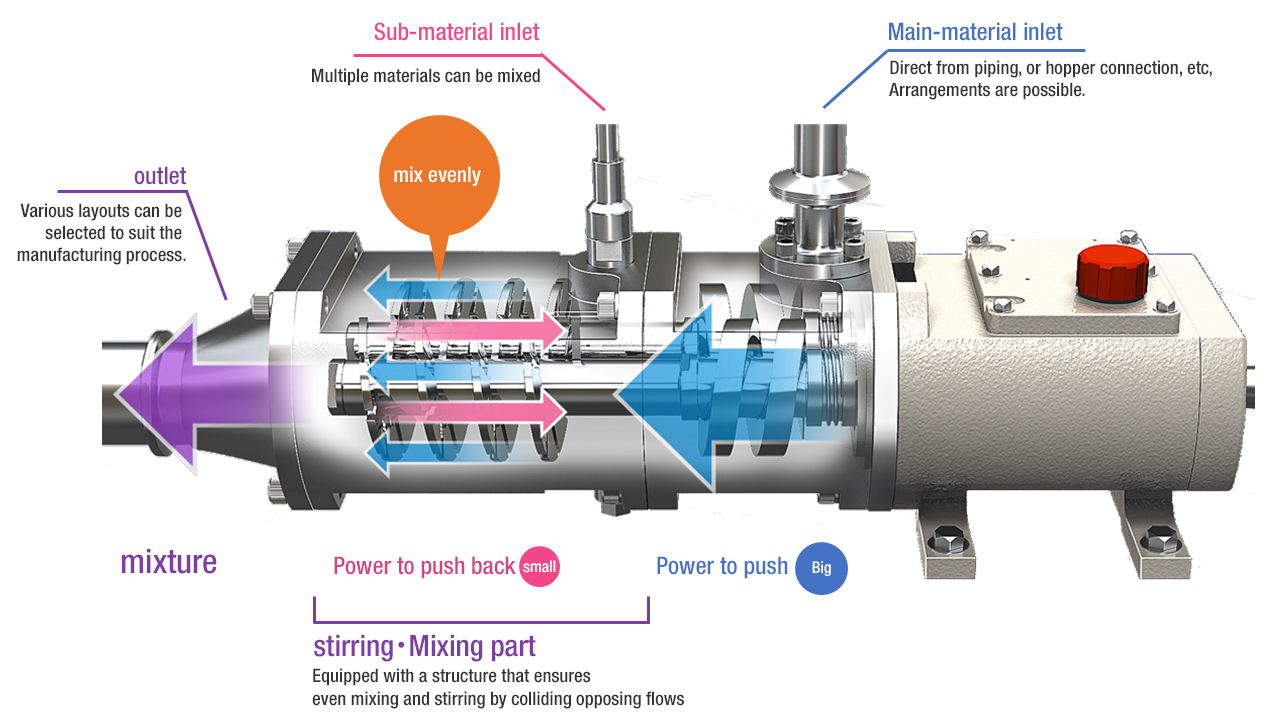

Function and structure of Blending Pump model BQ

Explanation video of the product

FAQ abiut products

Q

- keyboard_arrow_right

- Want to make continuous stirring process

- We are using batch type agitation,

Is it possible to change to a continuous type for higher efficiency?

A

The blending pump, which has both transfer and agitation functions, can be used to make the agitation process inline,

This can significantly improve production efficiency by changing from batch processing to continuous processing.

Q

- keyboard_arrow_right

- Want to reduce cleaning time for agitators

- I am burdened with disassembling, cleaning and reassembling the agitator, Is there anything you can do?

A

The use of a blending pump in the agitation process eliminates the need for an agitator and the time and effort required for disassembly and cleaning.

Instead, the blending pump needs to be cleaned,

The blending pump is a type that inherits the features of the sanitary twin-screw pumps with excellent washability,

which significantly reduces the cleaning time.

Q

- keyboard_arrow_right

- Want to suppress bubble generation by agitation

- When bubbles occur during the stirring process, I cannot proceed to the next process until the bubbles disappear… I would like to improve this…

A

Blending pump allows in-line agitation with as little external air as possible, minimizing the generation of bubbles.

FUKKO KINZOKU Industries customizes pumps to meet the needs of our customers, so please contact us even if you think it is difficult to realize your project.

We will recommend the best pump after discussion.

Please contact us for special liquids or liquids that you are having trouble with.

Main Specifications

| Connection method | Ferrule, IDF screw, JIS10K |

|---|---|

| operating temperature limit | 100°C (standard specifications) *Special specifications available up to 200°C |

| caliber | 1S to 3S,25A to 80A |

| Drive system | Direct coupling connection |

Standard materials of main parts

| Housing | FC250,SCS13 |

|---|---|

| Casing | SCS16,SUS316L |

| Screw | SUS316L |

| Shaft | SUS329J1 |