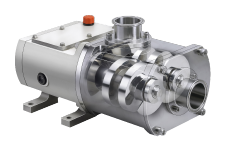

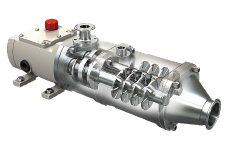

[Model used] : Twin screw pump with defoaming function, model VQ

[Liquid name] : minced meat

Purpose

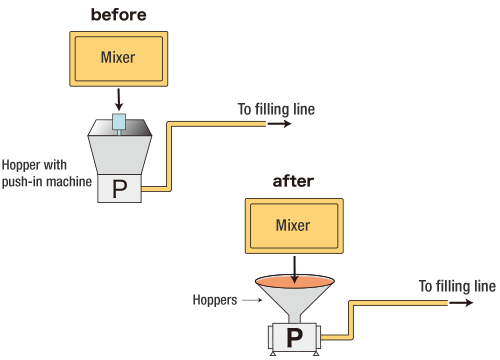

Reduced space for equipment installation and improved workability and safety

Problem

In the process of supplying minced meat from the mixer to the filling line, the following problems were faced with the existing progressive cavity pump.

・Although the pump had a strong suction force, it was not able to completely self-priming the minced meat, and it was necessary to feed the minced meat into the pump with the help of a pusher.

・The installation of a pusher squeezed the work space and affected work efficiency during disassembly and cleaning.

・Even during normal operation, the pump parts could wear out, and there was a risk of pump-derived contamination in the minced meat.

Points of improvement

A deforming pump was introduced.

Combined with a vacuum generator, the pump provides high self-priming power, enabling minced meat to be fed from the hopper to the inside of the pump without a pusher.

In addition, the following effects were obtained.

・The pump does not cause parts wear due to rotation, thus avoiding the risk of metallic foreign matter during normal operation.

・In addition to the simple disassembling and cleaning structure, the new pump provides more space for easier work, thus reducing the cleaning time.

・The machine can remove air bubbles from the minced meat during transfer, which reduces the rate of molding defects in the subsequent molding line.

production flow

Product used

Twin screw pump with defoaming function, model VQ

Non-contacting pump with high self-priming power.