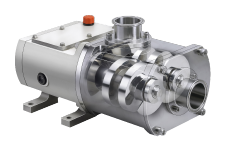

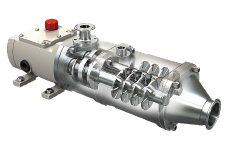

[Model used] : Twin Screw Pump with Defoaming Function Model VQ

[Liquid name] : gelatin

Purpose

Eliminates product waste due to molding defects

Problem

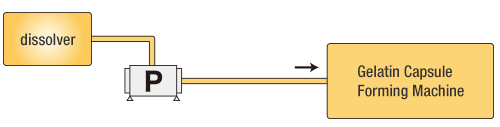

In a line that transfers dissolved gelatin from a dissolver to a capsule molding machine, the following problems were encountered with the existing equipment.

・The bubbles generated in the dissolving process were not eliminated before sending the liquid to the molding machine, resulting in many defective capsules in the final product.

・The company considered installing a vacuum tank to remove the bubbles, but there was not enough space to install a new tank.

・The foam that was generated did not disappear easily due to the high viscosity of the gelatin in liquid form, and static defoaming was not practical due to production efficiency.

Points of improvement

Twin-screw pump with defoaming function model VQ was introduced.

The following effects were achieved by this.

・The new pumps are designed to replace existing pumps, eliminating the need for a new installation space.

・The pump can remove bubbles contained in the liquid while pumping it, eliminating the need for waiting time for defoaming.

・The amount of air bubbles in the gelatin solution supplied to the capsule molding machine has been drastically reduced, and the incidence of defects in the final product has been greatly reduced.

production flow

Product used

Twin Screw Pump with Defoaming Function Model VQ

Achieves liquid pumping and defoaming at the same time.