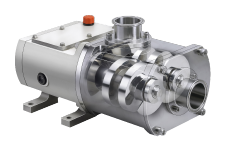

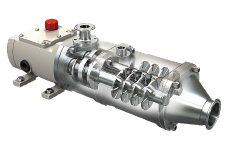

[Model used] : Twin Screw Pump with Defoaming Function Model VQ

[Liquid name] : grease

Purpose

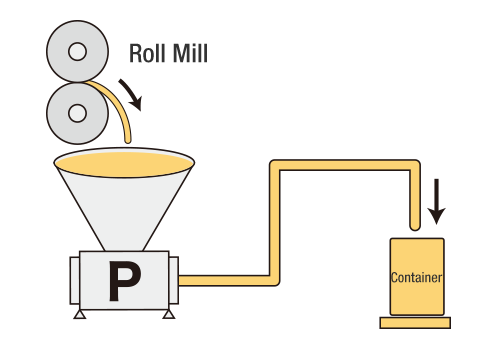

Efficient removal of air in grease and automatic supply from hopper to inside of pump

Problem

In a line where grease flowing in from a roll mill is filled into a container, the existing snake pump had the following problems.

・When air is compounded together with the liquid during roll milling, the air makes it difficult to suck the liquid from the hopper.

・When filling containers, air ruptures the liquid and causes it to scatter, getting the surrounding area slippy.

・Air causes filling accuracy to vary, and when the filling volume deviates, the filling volume must be adjusted manually.

・A snake pump, which is a contact type pump, has the risk of introducing foreign matter from the pump into the liquid.

What is a roll mill?

A device that pushes a high-viscosity liquid into the narrow space between multiple rolls and applies pressure to make the liquid uniform and finely disperse and compound solids contained in the liquid.

What is grease?

Semi-solid oil. It is mainly used for rotating parts such as bearings, and as a lubricant to reduce friction between them and the parts that hold them in place.

Points of improvement

A twin-screw pump with a defoaming function was introduced.

Because the pump can remove air bubbles from the liquid while transferring and has high self-priming power, it was able to eliminate poor suction from the hopper while drastically reducing the frequency of liquid splashing during filling and manual filling volume adjustments when filling volumes varied.

In addition, because the Model VQ pump is a non-contact type, contamination risk reduction was also achieved at the same time.

production flow

Product used

Twin Screw Pump with Defoaming Function Model VQ

Achieves liquid pumping and defoaming at the same time.