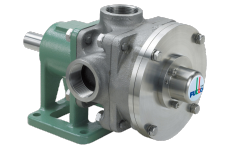

[Model used] : Small radial vane pump Model VBB

[Liquid name] : trivalent chromium liquid

Purpose

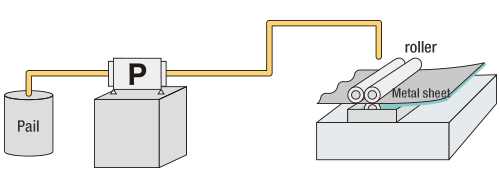

Coater supply from a pail

Problem

In a line supplying trivalent chromium liquid from a pail to a coater, the existing air-driven diaphragm pump had the following problems.

・The pulsation was so strong that the liquid would splash onto the sheet when supplied to the coater, resulting in a non-uniform film and the need for additional cleaning labor.

・When the flow rate is lowered to reduce the supply volume to control splashing, the suction capacity is reduced and it becomes difficult to pull the liquid out of a pail.

Points of improvement

A small radial vane pump was introduced.

Because the pump is less prone to pulsation, the liquid no longer splashes out when supplied to the coater, resulting in a more consistent, uniform coating and eliminating the need for cleaning.

In addition, the small size of the pump allows for fine flow rate adjustment, making it possible to supply the appropriate amount of liquid depending on the situation.

production flow

Product used

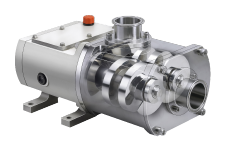

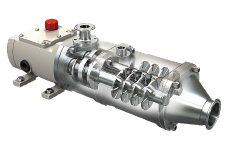

Small radial vane pump Model VBB

Easy disassembly and cleaning