Company Story

FUKKO pumps born from customer voice

“We would like to pull out the expensive raw materials which tend to remain at the bottom of the drum.”

The history of FUKKO pumps began with hearing such requests.

Although it is a completely unknown field,

With the experience of metal processing cultivated so far and tenacious research,

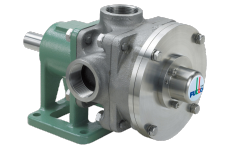

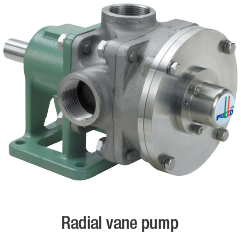

our first in-house manufactured radial vane pump was born in 1980.

Ever since,

V-type vane pump, which has the automatic pressure adjustment mechanism, was developed in response to requests for longer component life.

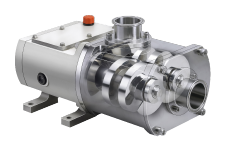

From the voice that “I’m looking for a positive displacement pump with a sanitary structure”

The twin screw pump, which is currently the main product, has been developed.

One-of-a-kind one products making further progress

After that, based on the ” problems” of our customers,

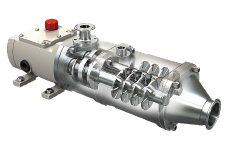

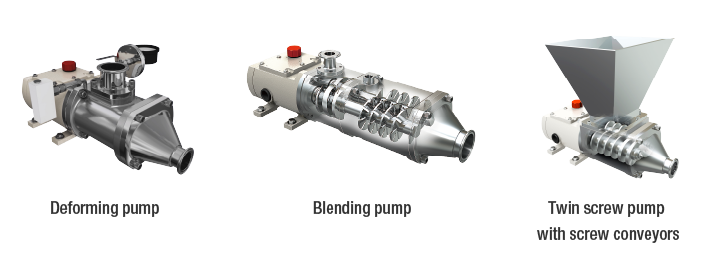

Twin Screw Pump with Slide Bar for easier disassembly and cleaning,

Twin Screw Pump with Screw Conveyor for transferring ultra-high viscosity liquid (Model SQW),

Twin Screw Pump with De-aerating Function (model VQ ) that realizes de-aeration and liquid transfer at the same time,

Twin Screw Pump with Agitation Function (model BQ) for mixing multiple liquids or liquids and powders while transferring them,etc.

We have created one-of-a-kind products one after another with unique ideas.

Our mission is “to develop original products that are truly useful.

These products are the result of tackling difficult problems that were previously thought to be “impossible.

Our origin is to stay close to our customers’ needs and respond to their wishes through creative, one-of-a-kind products.

Even if you think it is an impossible task,

Please feel free to contact us with your problems and concerns.

Company Profile

| trade name | FUKKO KINZOKU Industry Co., Ltd. |

|---|---|

| CEO / President | CEO / Representative Director Kanji Maeda |

| Head Office & Factory | 〒 640-8324 2-33 FUKIYA-Cho, Wakayama City, Wakayama Prefecture, Japan View googlemap tel +81-73-424-8155 |

| Kokawa Factory | 〒 649-6503 345-5 Nagatanaka, Kinokawa-shi, Wakayama Prefecture, Japan View googlemap tel +81-736-73-6161 |

| Tokyo Sales Office | 〒 104-0032 Shiobe Bldg. 3F, 4-9-6 Hatchobori, Chuo-ku, Tokyo View googlemap tel +81-3-3553-0351 |

| Capital stock | ¥10,000,000 |

| Founding | October 27, 1962 |

| Established | April 25, 1964 |

| Main bank | The Shoko Chukin Bank,Ltd. Wakayama Branch THE KIYO BANK, LTD. Higashi-Wakayama Branch MUFG Bank, Ltd. Wakayama Branch |

| Business Lineup | Manufacture and sale of radial vane pumps and twin screw pumps Processing of parts for refrigerators and air conditioners Machining of textile machinery parts Machining of parts for hydraulic equipment |

History

| 1962 | Mr. Kanji Maeda started machining at 2-3-1 FUKIYA-Cho, Wakayama City |

|---|---|

| 1964 | Incorporated as Fukko Kinzoku Industry Co., Ltd. |

| 1972 | With business expansion, the company was reorganized as a joint-stock corporation. Mr. Kusunobu Maeda took office of representative director & president, and Mr. Kanji Maeda, executive manager. Main office was placed at 2-33, Fukiyacho, Wakayama City. |

| 1980 | First original radial vane pump developed. Established an integrated system of development, manufacturing, and sales. |

| 1983 | Mr. Kusunobu Maeda retired as representative director and president, and took office of chairman. Mr. Kanji Maede took office of representative director & president. |

| 1987 | Mr. Kusunobu Maeda retired as chairman. |

| 1995 | Kokawa factory established at 345-5 Nagatanaka, Koukawa-cho, Naga-gun, Wakayama Prefecture |

| 2000 | Tokyo Sales Office opened. V-type radial vane pump developed. |

| 2001 | Twin Screw Pump developed. |

| 2005 | Tokyo Sales Office relocated |

| 2006 | VFP series compact vane pumps developed. |

| 2007 | Patent obtained for twin screw pump with screw conveyor |

| 2008 | Patented “Slide Bar” twin-screw pump |

| 2011 | Obtained ISO 9001:2008 certification (Certified offices: Head Office and Tokyo Sales Office) Received the Governor’s Commendation for Invention of Wakayama Prefecture in 2010 for the twin-screw pump. |

| 2012 | Developed twin screw pump with agitation function (model BQ) |

| 2013 | Developed twin screw pump with defoaming function (model VQ) Patent obtained for twin screw pump with defoaming function |

| 2016 | Developed improved twin screw pump (model SSQ) |

| 2017 | Selected as a “Regional Future Leading Company” (Ministry of Economy, Trade and Industry) |

| 2018 | Twin Screw Pump with Defoaming Function Selected “Kansai Monodzukuri New Award 2018” by the Ministry of Economy, Trade and Industry, Kinki Bureau of Economy, Trade and Industry |

| 2019 | Developed conveyor-integrated twin screw pump (SQWA type) |

Main Equipment

| High-precision multifunction machine(Turning center) | 10 units |

|---|---|

| Vertical machining center | 6 units |

| Vertical Machining Center(with 10-face pallet changer) | 1 unit |

| Vertical machining center (with 2-face pallet changer) | 2 units |

| Horizontal Machining Center(with 14-face pallet changer) | 1 unit |

| Horizontal Machining Center(with 3-sided pallet changer) | 1 unit |

| Horizontal Machining Center(with 2-sided pallet changer) | 3 units |

| NC lathe | 2 units |

| Wire cut | 1 unit |

| CNC Tapping Center | 1 unit |

| Grinding machine | 2 units |

| Drilling machines, etc | 5 units |

| Positioner, Press, etc. | 2 units |

| 3D Measuring Machines | 2 units |

| Surface roughness measuring machine | 1 unit |

| Shape measuring machine | 1 unit |

| Electromagnetic flowmeter | 2 units |

Main Clients

| Mitsubishi Electric. Refrigeration Systems Manufacturing Factory |

Osaka jack Co., Ltd |

| Nankai Industry Co., Ltd | Horiuchi Machinery Co., Ltd |